Ion pump is a vacuum pump used to create ultra-high vacuum, also known as sputtering ion pump or inert gas pump. There are various types of vacuum pumps, including ion pumps, which are classified as follows:

|

|

Low vacuum range |

High vacuum range |

|

Pump type |

Rotary vane pump

|

ion pump

|

|

Fluid state |

Viscous flow |

Molecular flow |

|

Conductive impact |

small |

big |

|

Exhaust diameter |

small |

big |

|

Example of flange |

DN16-40 |

DN63-400 |

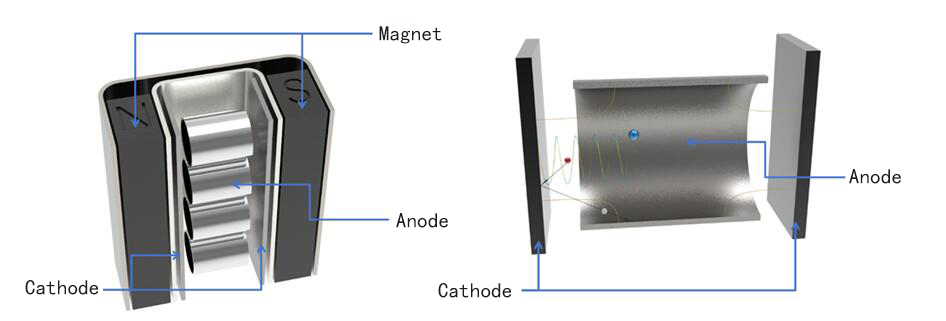

The ion pump consists of a strong magnet, a honeycomb shaped anode (anode array), and two titanium cathodes holding the anode. Therefore, its characteristic is that it does not have mechanical moving parts like a rotary pump.

Schematic diagram of ion pump: Structure of ion pump

When a cold cathode discharge occurs in a magnetic field, electrons emitted from the electrodes move back and forth between the two cathodes in a spiral motion under the action of the magnetic field.

When electrons collide with gas molecules, the gas molecules are ionized into ions. When these ions collide with the cathode, they will splash out titanium atoms on the surface of the cathode and embed them into the cathode.

In addition, the splashed titanium atoms will form a clean titanium film on the anode, cathode, and inner wall of the pump, called the suction film. Due to the chemical activity of the splashed titanium atoms, they will adsorb surrounding gas molecules during the process of forming a thin film.

Hydrogen, oxygen, nitrogen, carbon monoxide and other gases, as well as inert gases such as helium, will be ionized and embedded in the cathode or adsorbed by titanium atoms. As a result, the number of gas molecules in the surrounding environment will decrease. In this way, the ion pump creates a vacuum state.

(1) Under high pressure, electrons are emitted from the titanium cathode and move back and forth between the two cathodes in a spiral motion.

(2) Electrons collide with gas molecules, and gas molecules are ionized to form ions.

(3) Ions collide with the titanium cathode, sputtering titanium atoms and embedding them into the cathode.

(4) In addition, the splashed titanium atoms form a layer of titanium film called a gas absorbing film, which adsorbs gas molecules.

Ionic pumps do not rely on mechanical devices to extract air like centrifugal pumps do, but create vacuum by causing chemical reactions in the existing air and consuming it.

You can imagine a science experiment in elementary school: placing a candle in a bottle with the mouth facing downwards, letting the bottle float on the water surface and burn. As oxygen is consumed, water will be drawn into the bottle accordingly, making it easier to understand the working principle of an ion pump. When there is no more gas, the resistance between the anode and cathode will increase, which will cause the current to stop, thus confirming the completion of pumping.

The characteristic of an ion pump is that it can achieve a high vacuum state regardless of the gas type. Therefore, they are applied in fields such as transmission electron microscopy, electron beam lithography equipment, accelerators, and semiconductor manufacturing equipment.

Characteristics of ion pump

The advantages and disadvantages of ion pumps are as follows:

advantage

shortcoming

One major advantage of an ion pump is its simple mechanism, which only requires applying voltage to the electrodes in a magnetic field to achieve a high vacuum state without mechanical vibration and noise. Therefore, it is widely used as a vacuum pump for electron microscopes and semiconductor manufacturing equipment, which require both high vacuum environments and precise control.

The ion pump itself is not large in size, even the largest ion pump is usually small enough to be placed on a table.

When there is no exhaust gas available, its power consumption will decrease, and even if the pump stops working, there will be no oil or other pollutants flowing back to pollute the exhaust area. Therefore, it is suitable for long-term unmanned operation and is widely used as a vacuum pump to maintain vacuum.

On the other hand, one of its drawbacks is the difficulty in performing high flow pumping. In most cases, the starting pressure of an ion pump is around 1 pascal. Therefore, in order to achieve ultra-high vacuum, the usual approach is to first use other pumps to create a high vacuum state, and then use an ion pump for final pumping and maintenance.

In addition, if impurities are adsorbed inside the pump, it will affect the pumping effect, so baking must be carried out in advance to remove impurities. Moreover, the titanium of the cathode will be sputtered and deposited on the inner wall and other parts of the pump, so it has a certain service life and needs to be replaced at the appropriate time. Another disadvantage of ion pumps is the need for high pressure. The commercially available ion pumps are designed to operate at voltages of 3 kV, 5 kV, or 7 kV. In addition, the power supply current and power used vary from tens of watts to hundreds of watts depending on the pumping speed and size.